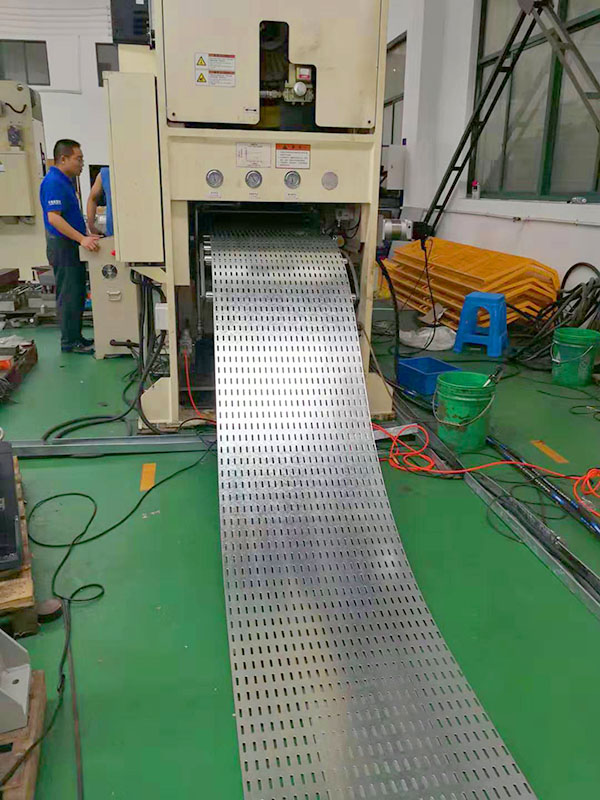

Sihua Cable Tray Roll Mashiinka Samaynta

Mashiinka samaynta duubida saxaarad fiilada (sidoo kale loo yaqaan mashiinka samaynta duubka jaranjarada fiilada) ayaa awood u leh samaynta cabbirro kala duwan ee saxarada fiilooyinka iyada oo la beddelayo caaryada feeray. Xirmooyinka fiilooyinka ee ay soo saartay duubkan samaynta khadka wax soo saarka mashiinka ayaa si weyn loogu isticmaalaa warshadaha iyo dhismayaasha kale. Sababtoo ah adkeysigooda saxda ah. Mashiinka samaynta duubida saxaarad fiilada waxa ay ka kooban tahay decoiler(uncoiler),mashiinka bixista(leaver), servo feed device, feeding system, qalabka goynta hore, qalabka hagaya, duubkii hore, qalabka toosinta danbe iyo miiska soo baxay.

Iyadoo waayo-aragnimo buuxda oo gaar ah, waxaan astaysto kartaa mashiinada duubo saxaarad cable samaynta ama cable saxaarad duudduuban samaynta khadadka wax soo saarka sida ay macaamiisha"sawiro profile iyo qeexidda.

| Magaca | Unugyo | Tirada | |

| Qalabka wax lagu nadiifiyo | Deji | 1 | |

| Mashiinka ugu muhiimsan | Lever, Quudiye, | Deji | 1 |

| mashiinka samaynta | Deji | 1 | |

| Qalabka Goynta | Deji | 1 | |

| Nidaamka Haydarooliga | Deji | 1 | |

| Nidaamka xakamaynta korantada | Deji | 1 | |

| Miiska xirxirida | Deji | 1 | |

1. Tiknoolajiyada Talyaaniga mashiinka samaynta duubista tayada Jarmal.

2. Mashiinka samaynta duubista saxda ah ee xawaaraha sare ee profile aad u fiican.

3. Mashiinka noocan oo kale ah ayaa leh tayada ugu fiican iyo qiimaha ugu fiican. Waxay leedahay cabbir sax ah iyo hawlgal sahlan.

4. Waxaan naqshadeyn karnaa oo soo saari karnaa mashiinka nooca gaarka ah iyadoo loo eegayo shuruudaha macaamiisha waxaanan bixin karnaa hagitaan farsamo, wax soo saar, rakibaad, cillad-dejinta iyo dayactirka dhammaan macaamiisha.

5. Badeecadeena waxaa loo dhoofiyay gobollo badan waxaana lagu helay sumcad sare sababtoo ah tayada sare iyo qiimaha qiimaha leh.

Mashiinka Samaynta Cable Tray Roll ee daloolku waa khad wax-soo-saar labaplex ah iyo wax-soo-saar sare oo loogu talagalay soo saarista astaanta qaybta C oo leh godad godad leh oo lagu taageerayo fiilooyinka korantada ee dhismaha ganacsiga iyo warshadaha. Saxaarada fiilada oo ay soo saartay Cable Tray Roll Samaynta Mashiinka sida caadiga ah laga sameeyay dhumucdiisuna waxay tahay 0.8 ~ 2.0mm.

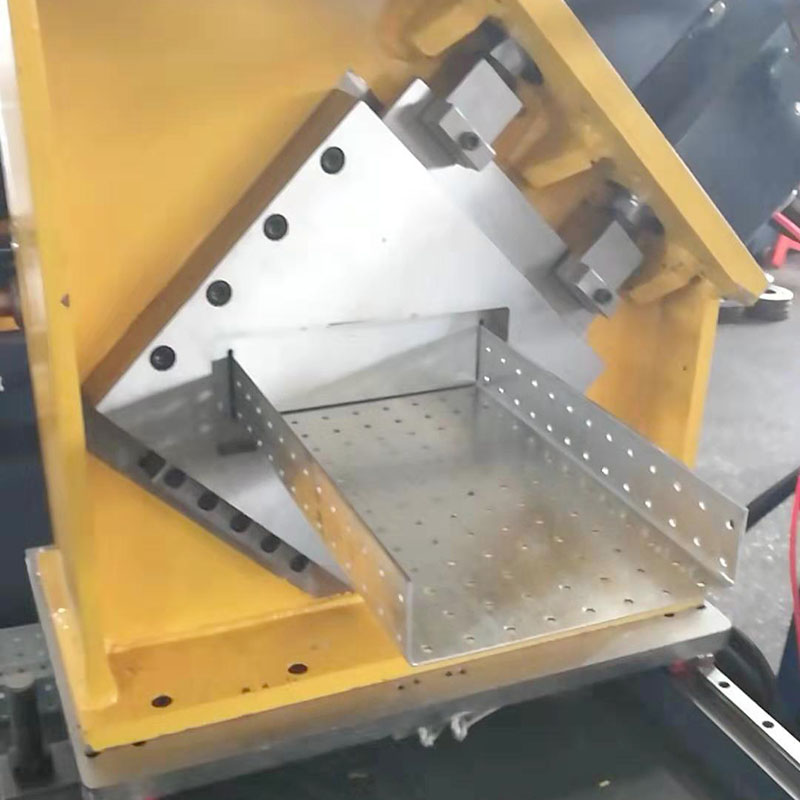

Mashiinka Samaynta Cable Tray Roll ee daloolku wuxuu si guul leh isugu daray aaladda feerka haydarooliga ama mishiinka xawliga sare leh ee godadka shucaaca ee saxaaradda fiilada. Sidoo kale, shafka telescope-ka ayaa diyaar u ah inuu si degdeg ah u beddelo cabbirka iyada oo aan la beddelin lacagta. Goynta ka hor ama goynta ka dib labaduba waxay u qalabaysan karaan alaabta la gooyay.

Mashiinka Samaynta Wareegga Fiilada oo dhan oo ay ku jiraan Decoiler, Aaladda Hagaha, Rollallallada Toosan, Mashiinka Samaynta Roll-ka-Maal, Nidaamka Haydarooliga, Nidaamka xakamaynta PLC iyo miisaska Ran-out. Mashiinka samaynta duubkayaga oo ku qalabaysan nidaamka xakamaynta kumbuyuutarka. Waxa aad u baahan tahay oo kaliya in aad kumbiyuutarka ku program-garayso qaybta iyo dhererka aad u baahan tahay, ka dib mishiinka samaynta duubka ayaa si toos ah u soo saaraya. Mashiinku waa sahlan tahay in la shaqeeyo, oo si deggan u shaqeeyo.

| Qalab saxan ku habboon | |

| Maad - dhumucdiisuna | 0.8-2.5mm |

| Wax cayriin | Bir galvanized iyo go'yaal bir madow ah |

| Xawaaraha shaqada | 15 mitir / daq |

| Samaynta Tallaabooyinka | 8 saldhigyada |

| Qalabka Roller-ka | cr12mov |

| Qalabka Shaft | 45# Birta Hormarsan ( Dhexroorka: *90mm), sifaynta kulaylka |

| Nidaam wado | sanduuqa gear, dhexroorka ulaha 70mm |

| Awoodda ugu weyn oo leh wax yareeya | 22KW SIEMENS |

| Goynta | Goynta Haydarooliga |

| Qalabka goynta garbaha | SKD11 (JAPAN) |

| Korontada Saldhigga Haydarooliga | 11KW SIEMENS |

| Mashiinka oo dhan waxaa gacanta ku haya kombuyuutar warshadeed-PLC | |

| PLC --Mitsubishi Japan | |

| Shaashada taabashada—KINCO | |

| Qaybaha korantada - Schneider | |

| Ku hagaaji dhererka matoorada iyo biraha, oo ay maamusho PLC | |

Sawirka mishiinka fiilada